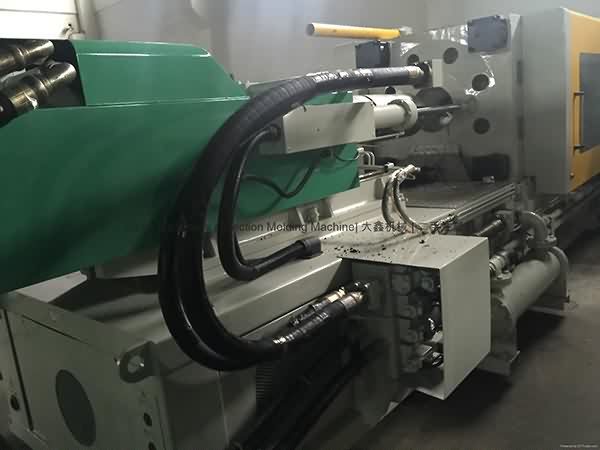

Factory selling Chen Hsong Super Master SM450TS used Injection Molding Machine to Berlin Importers

Factory selling Chen Hsong Super Master SM450TS used Injection Molding Machine to Berlin Importers Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Factory selling Chen Hsong Super Master SM450TS used Injection Molding Machine to Berlin Importers, The product will supply to all over the world, such as: Danish , Nigeria , Hongkong , We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

https://www.vsrsuperfinishing.com

HB-superfinishing machine

HB-superfinishing tool

Whatsapp:+86 15866605088

wechat:brady0086

Skype: brady0086

QQ:1156692876

TEL: +86 183 40057108

CELL: +86 15866605088

E-mail:brady0086@hotmail.com

JINAN ZHAOYANG MACHINE CO., LTD

JINAN HUABAO MACHINERY CO., LIMITED

ADD:No.6 Qilihe Road,Jinan,Shandong,China,250001

Contact: Mr. Brady

Great Innovation For Metallic Surface Superfinishing &

Provide Complex Problems Solutions

Superfinishing machine

Great innovation for superfinishing;replace polishing,grinding,rolling;non-abrasive superfinishing.....

The brief:

1. Obtain surface roughness less than Ra0.1 easily;

2. Suitable for different shapes, such as cylindrical, internal, rotor, curved and spherical, axis,etc;

3. Suitable for all kinds of materials, such as carbon steel, aluminum alloy, copper, etc;

4.Suitable for different industries, such as Turbine, Mining machinery, Mechanical valve, Petroleum Machinery, Bearing mechanical, Mold, Paper machinery, Pharmaceutical Machinery centrifuge, Piston rod, Hydraulic cylinder, Helical rod, Metallurgical Machinery, Wind power, Hydropower, Motor.

5.Can be used in all kinds of machine tools, such as lathe, grinding machine, boring machine, milling machine, planning machine, spherical lathe and CNC machine tools, ect;

6. Just one time, improve production efficiency greatly;

7. Components: tool assembly and control-center;

8. Improve the micro-hardness 20%;

9. Improve the wear-resistance;

10. Improve the fatigue life 5 ~100 times;

11. Suitable for the hardness below HRC65;

12. Improve corrosion resistance;

13. It's a nonabrasive process, without abrasive, felt, lapping compounds and hard work.

14.Relieve the residual stress greatly;

15.Long service life of tool and workpieces;

16. It saves time, money and energy;

17. No sawdust and sawdust wastes occurred,no noise and damage to the environment;

18.Easy to operate.

The principle:

According to metallic materials cold plastic deformation in the normal temperature and apply HB-superfinish equipment to superfinish the surface without any abrasive to reach desirable roughness,this process just like ironing clothes.

The process:

Firstly, make the workpiece pre-machining in the general purpose machine, then apply HB-super finishing equipment again, the roughness will reach less than Ra0.1 easily, just like ironing the clothes and a kind of compressive stress created on the surface at the same time, the micro-hardness will be improved more than 20%, the wear resistance will be improved greatly and the life will be improved 5 ~10 times.

The description:

This equipment including two parts, one is cutter, the other is control center,

the cutter is controlled by control center,

there is a unstable ball which made from a special materials on the cutter head,

during process, the ball impacts the surface 30,000 times per second with very little pressure about 2.5N,

the temperature is little higher than the normal temperature,

it's a nonabrassive process, without abrasive, felt, lapping compounds and hardwork,

save time and cost greatly, and very environmental,

it's very different from the rolling, polishing, grinding and other process,

more precisely, it just like ironing the clothes, never remove any materials from the surface.

https://www.vsrsuperfinishing.com

HB-superfinishing machine

Whatsapp:+86 15866605088

wechat:brady0086

Skype: brady0086

QQ:1156692876

TEL: +86 183 40057108

CELL: +86 15866605088

E-mail:brady0086@hotmail.com

JINAN ZHAOYANG MACHINE CO., LIMITED

Former JINAN HUABAO MACHINERY CO., LIMITED

ADD:No.6 Qilihe Road,Jinan,Shandong,China,250001

Contact: Mr. Brady

Watch this video to see how the latest MAGMASOFT® metal flow simulation technology enables RCM’s engineers to determine the best process parameters for ensuring part quality.

Before production, our simulation experts use RCM’s industry leading gate and runner design techniques to determine the best point to inject molten metal into a die, ensuring you receive finished parts with the best density and structural features possible.

Discover More @ RCMIndustries.com

Call 847-455-1950

Email us at sales@rcmindustries.com

Subscribe for more videos!

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.