High Quality for JSWJ1300EIII used Injection Molding Machine – Used Mould

High Quality for JSWJ1300EIII used Injection Molding Machine – Used Mould Detail:

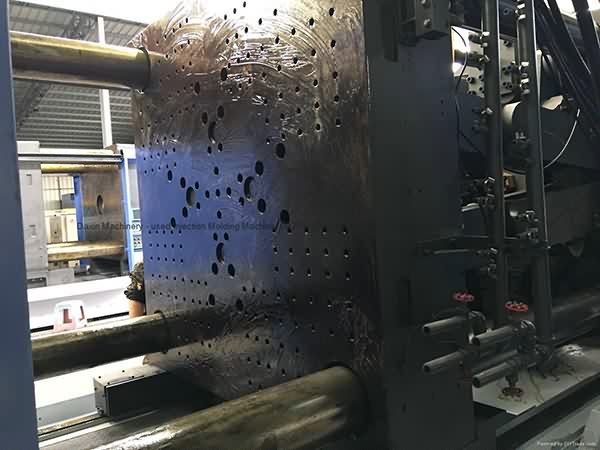

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for High Quality for JSWJ1300EIII used Injection Molding Machine – Used Mould, The product will supply to all over the world, such as: Belize , Oman , Salt Lake City , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

MMC has been supplying cap slitters and TE band inverting machine systems to the closure industry for many years and has advanced the field through innovative machine design.

a) Knotched Knife Slitting Technology

Rotary Cap Slitting machines score the side wall of your plastic closure with arched slitting blade. The slitting blade has intermittent interruptions that will leave a predetermined amount of bridges to hold the Tamper Evident Band to the closure. When the closure is removed from the container for the first time, the bridges break, leaving the band on the neck of the container and demonstrating visual point of purchase tamper evidence to the consumer.

b) Cut-to-post Slitting Technology

A series of ribs are molded into the inner wall of the closure, which will eventually become the bridges that break during closure removal. The closure is rotated against a stationary blade, gradually slicing through the side wall until the blade reaches the molded-in posts.

c) Band Inverter

MMC has launched the CMBF product series to streamline the Tamper Evident Band folding and Band inverting operation. Our unit is a fully automatic multiple head continuous motion machine which is able to fold in the Tamper Evident Band retaining feature allowing the container neck to grip this feature.

For more information, please visit our website

www.mmcpackaging.com

Fully-automatic PET Bottle Blow Molding Machine adopt Siemens PLC & Touch Screen,Germany Festo pneumatic system,Japan Mitusbishi Servo Motor ,high ...

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!