Personlized Products Haitian 380t used Injection Molding Machine Supply to Paris

Personlized Products Haitian 380t used Injection Molding Machine Supply to Paris Detail:

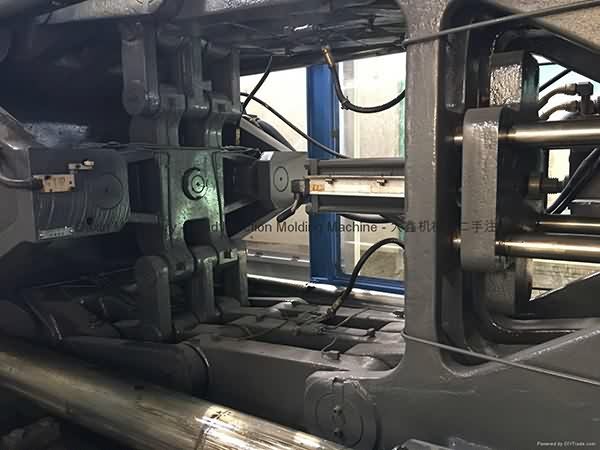

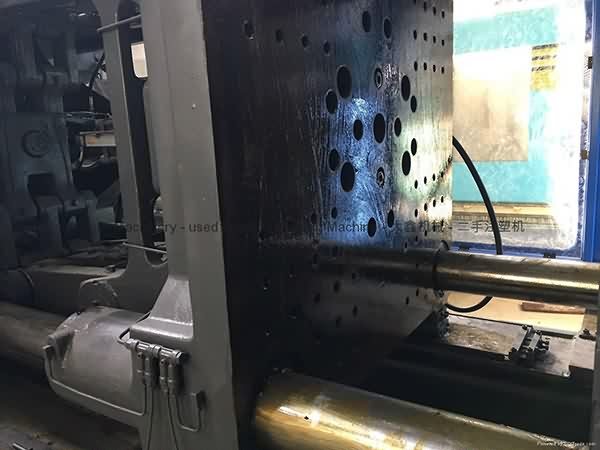

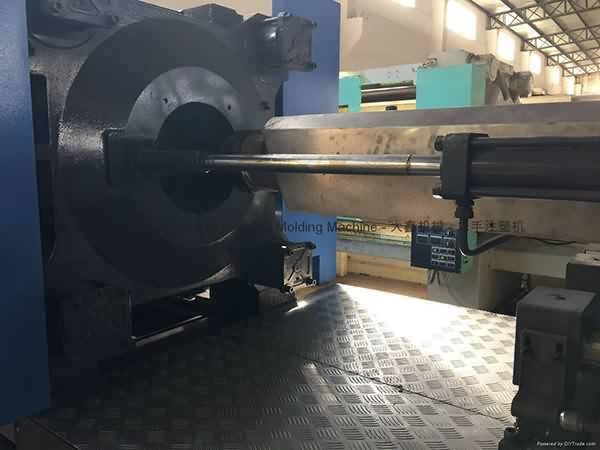

Haitian 380t used injection molding machine .

Model: SA3800/2250v.

Year : 2010.

Screw type: B-D70.

Tie bar spacing: 720x720mm

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

"Based on domestic market and expand overseas business" is our development strategy for Personlized Products Haitian 380t used Injection Molding Machine Supply to Paris, The product will supply to all over the world, such as: Tanzania , Manila , Czech republic , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

It's a short video of our ZX-7.5KW production inline homogenizer tested by water. The 30L stainless steel powder hopper is double jacketed with insulation. To learn more about our ZX-7.5KW/10HP production inline homogeniser, please visit our website here: https://www.ginhong.com/products/high-shear-mixer/inline-homogenizer/.

What is production inline homogenizer?

ZX production inline homogenizer, usually called inline high shear mixer, is an inline mixer for the manufacturing of viscous cream, lotion and other emulsions in the cosmetic, pharmaceutical, food and chemical industries. It’s the heart of our RB vacuum emulsifier mixer and is suitable for continuous mixing.

What is production inline homogenizer made of?

ZX high shear inline mixer is usually made of one set of rotor and stator, mechanic seal, transmission part and motor etc. The body of the in line mixer is mounted on a stainless steel base. An inlet and outlet ports are used to connect to the manufacturing vessel for circulation. A drain port is opened at the bottom of the chamber for cleaning purpose.

How does production inline homogenizer work?

The rotor of the in line mixer is driven by ABB or Siemens motor and rotates at the speed of 3000rpm causing strong centrifugal force. The raw materials are sucked from the inlet of the stator into the high shear mixing chamber.

The strong centrifugal force drives the product to the narrow gap between the rotor and stator. The product is pressed and crushed by the centrifugal force and then got dispersed, homogenized and emulsified preliminary.

Meanwhile, the rotor produces a linear velocity up to 15~40m/s along the tangent. The product goes through the gap between rotor and stator and is dispersed, high sheared, emulsified and homogenized. Then it jets out from the outlet of the high shear mixing chamber.

Because the high shear in line mixer is usually mounted with a mixing tank by circulation pipes, the product is sucked from the bottom of the tank, jets out from the pipe and then goes back into the tank. After several circulations, it’s completely high sheared, dispersed, emulsified and homogenized.

Key features of production inline homogenizer

Complete process of dispersing, high shearing, emulsifying and homogenizing

Flow rate by water from 1.5m³/h to 110m³/h

Suitable for making cream, lotion, ointment and other emulsions of 5,000~100,000cps viscosity

Suitable for continuous mixing process of large quantity with high efficiency

High shear inline mixer with circulation pipes to the mixing tank for even homogenization

Products can’t bypass the precision rotor and stator workhead

The self-pumping in line high shear mixer also works as a transfer pump for discharging finished product

Cooling system for the mechanic seal for longer high shear mixing time

Work with different manufacturing vessels

All Ginhong inline high shear mixers are designed for CIP and SIP

All contact parts are made of SS316L/304

Sanitary clamp connections for inlet and outlet ports

The specifications of the inline continuous mixer comply with cGMP regulations

Power supply of 380V, 50Hz, 3 Phase

WE ARE THE BEST PLASTIC MACHINE SUPPLIER: PET semi-automatic stretch blow molding machine Automatic stretch blow moulding machine ...

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.