professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers

professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers Detail:

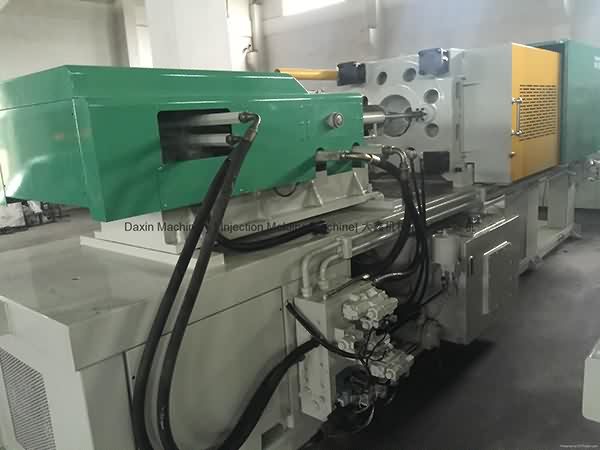

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers, The product will supply to all over the world, such as: London , Korea , Guatemala , We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity

Automatic Stretch blow molding machines, pet blowing machines for wide mouth plastic jars

Features:

The Precision design of the elbow-type hydraulic clamping mechanism to ensure that the clamping force of the foot, the action is not smooth expansion.

The Slide drive to ensure smooth running, fast and accurate.

The Self-locking high-pressure sealing, sealing reliable, no impact, no wear; independent control of the drawing rod, stretching process control accuracy.

The With automatic bottle machine, optional automatic loading blank device, to achieve the production process fully automatic.

The A new generation of industrial-grade high-speed PLC control computer and Chinese and English touch screen operation interface, process time parameters set to accurate to 0.01 seconds, making the operation more intuitive, more accurate process settings.

The Part of the action part of the pneumatic components used in Europe or Japan high-quality components. High pressure blowing Germany quick response solenoid valve, so that the timing of the second blowing accurate control.

The Concentrated parallel heating to ensure uniform heating, stability, and minimize energy consumption.

The Closed-loop feedback precision instrumentation heating control, import high-power power module output to ensure stable heating and energy saving, not affected by voltage fluctuations. To the most effective infrared heating PET heating wavelength, in particular, customized heating lamp, to achieve the highest energy efficiency, fully consider reducing energy consumption and improve production efficiency.

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.

For more information about penglai packaging, please visit our website at https://penglaipacking.com

SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

Contact:Michael Peng Skype: penglaichina Email: penglaipacking@gmail.com whatsapp:+86-15012795261

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!